|

Penetrant inspection depends mainly on the ability of liquid to wet the surface

of a solid work piece or specimen and flow over that surface to form a continuous

and reasonably uniform coating, thus penetrating into cavities that are open to

the surface. Capillary action attracts the fluid to the discontinuity as compared

to its surroundings.

Liquid penetrant test method enhances the visibility of surface breaking flaws such

as cracks, fissures, crevices and pores. It can be used very successfully regardless

of component size and can tolerate complicated part geometry.

LIMITATIONS -

1. The discontinuity to be detected must be open to the surface and the interior

free from foreign materials.

2. The test surface should not be porous.

3. The material under test must not be susceptible to damage from the liquids used

for the examination.

5. Detection of surface flaws depends on the general condition and finish of the

test surface.

4. Defect detectability can be diminished by normally acceptable surface conditions

such as tool marks, scratches, scale, edges, grooves, notches, rough weld surfaces

etc, where penetrant is trapped.

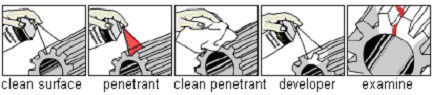

TEST PROCESS

1. A penetrating liquid is applied to the clean and dry test surface and allowed

to enter the discontinuity opening over a period of time . The liquid seeps into

material flaws that are open at the test surface.

2. After a suitable penetration time, the excess surface penetrant is removed and

the test surface is dried

3. A developer is then applied in a thin uniform coating which acts as blotter and

draws some of the entrapped penetrant out of the discontinuities.

4. The penetrant stains the developer and the indication becomes visible. Visual

inspection is the final step in the process.

The dye indicator appears either red or blue on a white background for color contrast

penetrants. For a fluorescent test process, it appears Yellow - green or orange

- red on a dark violet background, where the surface is illuminated by an ultraviolet

lamp. The penetrant used is often loaded with a fluorescent dye and the inspection

is done under UV light to increase test sensitivity.

|